|

Standard Size – 8’ x 4’

Thickness - 3,4,6,8,12,15 & 18mm

RAW MATERIALS

FSD BWP Marine Plywood is made of selected 100 per cent Gurjan Timber (Dipterocarpus species). Classified under Class-I, this is a naturally durable timber from the richest Gurjan timber forests in Myanmar.

ADHESIVE

Bonded with Boiling Water Proof type PF resin under high pressure and temperature.

CONSTRUCTION

Consecutive veneer's, which are full-length veneers, are cross-laminated, with face veneer thickness of 1.2mm for higher abrasion resistance and improved mechanical properties at the end use. Core veneers between both the face veneers are of equal thickness, having similar and uniform physical and mechanical properties, to ensure absolute balance construction.

PRESSING

After assembling the veneers as per the specific construction, it is pre-pressed. The pre-pressed plywood is the hot-pressed under high pressure and controlled temperature for better compression to produce a dimensionally stable and wrap free plywood.

TREATMENT

The final product is treated with CCB preservative solution with high retention of preservatives.

GRADE

FSD BWP marine Plywood is manufactured as per BS, DIN and JPIC international standards and not only confirms but also exceeds the specification of IS:710-1976 BWP Marine Plywood.

DURABILITY

At the crossroad of nature is a need. The engineered quality plywood will provide you with extra satisfaction.

APPLICATIONS

- Kitchen Cabinets

- False Ceiling

- Ship Cabins

- Bathroom Paneling

- Bus and Truck Bodies

- Freight Containers

- Construction Works

- Porta Cabins

- Bunker House, etc.

|

|

|

.: BWP Film-Faced Plywood :.

This International Quality Plywood Is The Favourite Amongst Builders, Developers And Contractors.

Standard Size – 8’ x 4’

Thickness - 12mm

The basic plywood is made up of special selected hardwood and boned with synthetic / phenol formaldehyde resin, overlaid with phenolic film, and edges are sealed with polyurethane paints. It generally meets the requirements of BS 6566 / WBP, DIN 68705 / BFU 100 or JPIC 1968 / 1973 and IS:4990 – 1993, and is suitable for High Quality Concrete Shuttering Formworks.

FSD Shutting Film-faced Plywood is suitable for all Shutting Systems :

- Wall Form

- Table

- Tunnel

- Cast -in-Situ

- Special Casting

- Columns

- Walls

- Beams

- Slabs

- Any kind of vertical and Horizontal Concrete Formworks

|

|

.: Premium Commercial Plywood :.

It is being manufacture at a state - of - the - art plant located in South India, with ISI Certified Quality Mark and a ISO 9002 - 1994 Quality System.

It is being manufacture at a state - of - the - art plant located in South India, with ISI Certified Quality Mark and a ISO 9002 - 1994 Quality System.

. .

This General Purpose Plywood is made from selected durable species of timber, hot pressed and bonded with synthetic resin adhesive.

APPLICATION

Ideal for use in Interiors of Offices for paneling, Partitions, Cabinets, Shelves, Cupboards, Computer Furniture and tables, for Living Room and Bedroom and Furniture in Residences, etc.

| Thickness mm |

Sized mm |

| 3,4,6,9,12,15,18,25 |

2440 x 1220 / 920

2140 x 1220 / 920

1840 x 1220 / 920 |

|

.: Block Boards :.

Is made from solid wood core of uniform strips joined together with cross band, faced on either sides with commercial and / or Teak veneer confirming to IS : 1659 - 1990.

Available in two types - Exterior Grade Commercial / Decorative Block Boards, and Interior Grade Commercial / Decorative Block Boards.

The Block Boards are made from a single variety of hardwood batons, used with compressed quality veneers to make the best quality warp free and smooth surfaced block boards. These Block Boards are ideal for Good Strong Support to Specialty Woodwork.

APPLICATION

- Furniture

- Cupboards Shutters

- Bank Counters. etc.

| Thickness mm |

Sized mm |

| 19,25,30,35,40 |

2440 x 1220 / 920

2140 x 1220 / 920

1840 x 1220 / 920 |

|

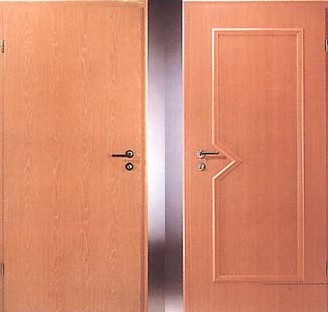

.: Flush Doors :.

|

Made from hardwood styles and rails with block boards core, cross bands and face veneers are bonded together under heat and pressure using BWP type PF synthetic resin adhesive confirming to IS : 2202 : 1991

Flush Doors are available in three types :-

-

COMMERCIAL - with face veneers from selected commercial hardwoods.

-

DECORATIVE - with one or both sides face veneers from decorative timers like Teak.

-

LAMINATED - with laminates of customer's choice. The cross-bonds are from select hardwood, uniformly dried to the required moisture content and then bonded with special phenol formaldehyde synthetic resin. Flush Doors are chemically treated for termite and borer resistance.

|

|

| |

Available in standard sizes and also made to required sizes.

Available Standard Thickness - 30,32,35,38,40, & 45mm. |

|

|

|

|

|